WHICH SUBJECT ARE YOU INTERESTED IN?

We are looking forward to hearing from you.

Call us:

+49 (0)7308 811 499 0

We are pleased to contact you!

Send us an e-mail to

info@busse-production.com

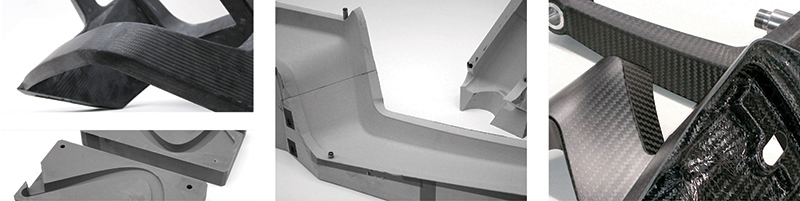

In cnc manufactured toolmaking, whether for CFRP and GFRP parts, plastic thermoforming or foams, one thing is essential:

Cost efficiency and speed in the construction of the mould! Does this sound familiar? The deadline is tight, but the procurement of the raw material and the lead-time of the mould is already beyond schedule and budget.

BUSSE Production offers the solution:

+ Up to 50% material cost savings

+ Rapid raw material availability

+ Up to 50% less machine time through higher cutting speeds

+ Large moulds can easily be assembled from individual blocks

+ Simpler post-processing and repair, hence cheaper and faster response time to mould modifications are possible

+ Surface quality identical to aluminium, finish possible by fine sanding and painting

+ Optional mould design by our own engineers

Dipl.-Ing. (FH) Christian Gemperlein

(CEO all ahead composites GmbH)

|

High temperature resistant

plastic |

aluminium | |

|

density

|

0,68 g/cm² | 2,7 g/cm² |

| temperature resistance | up to 145° | up to 250° |

| material price per 1m³ | 8.840 €/m³ ( ~ 13 €/kg) | 17.550 €/m³ ( ~ 6,5 €/kg) |

| procurement times | within 48h | in large blocks significantly longer |

| resilience | Autoclave: about 10 pieces Glass fiber reinforced polyester about 300-1,000 pieces |

about 1,000 pieces |

| in autoclaves | suitable |

suitable |

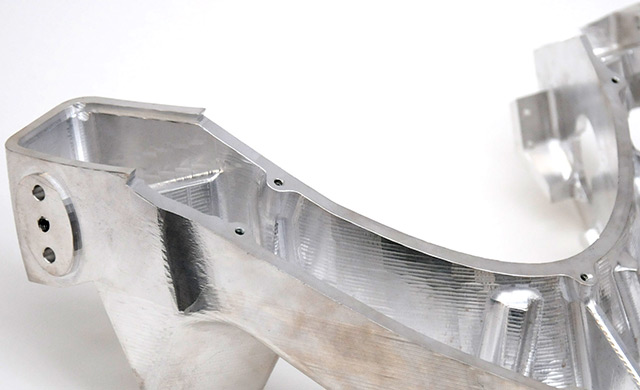

Thanks to modern CNC machine tools, intelligent CAD-CAM programming and a 1,000 square meter facility, complex free-form surfaces and parts can be manufactured in small batches at BUSSE within a very short lead-time.

Materials:

All types of plastics, aluminium, magnesium, brass, Non-ferrous metals of all kind

Thanks to further in-house options, we also offer from one source:

Finishing & polishing, painting and powder coating, incorporation of functional kinematics, welding, assembly and function testing, preparation of complete prototypes

EXCERPT FROM OUR CNC MACHINERY:

|

traversing: | x 2.000 mm |

| y 1.000 mm | ||

| z 600 mm | ||

| rotation speed: | 24.000 1/min |

5-axis CNC machining centre with minor

amounts of lubrication and vacuum chuck

|

traversing: | x 600 mm |

| y 525 mm | ||

| z 500 mm | ||

| rotation speed: | 12.000 1/min |

Universal 3-axis milling and drilling machine with

Minor amounts of lubrication and vacuum chuck

ADDITIONAL VALUE:

IN-HOUSE ENGINEERING EXCELLENCE

CAD Systems:

+ Solid Works

+ ProE / Creo

+ Inventor

CAD/ CAM Systems:

+ Cimatron (E12)

We are looking forward to hearing from you.

+49 (0)7308 811 499 0

Send us an e-mail to

info@busse-production.com